- About

- Mining

- Energy Group

- AmerCable Systems

- Industrial

- Renewable Energy

- What's NEW @ AmerCable?

- Contact us

Mining

RFID-Enabled Mining Cables Now Shipping!

May 1, 2020

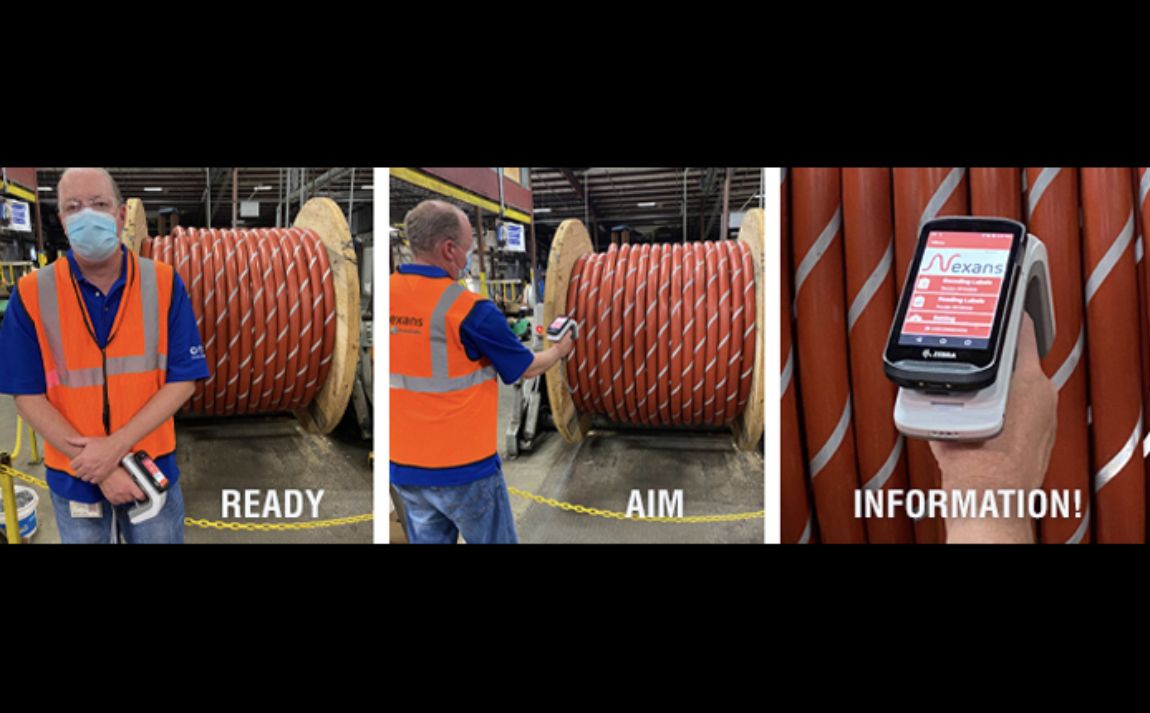

Nexans AmerCable, the leader in mining cable innovation, is pleased to introduce our newest value-added cable enhancement – RFID-enabled SHD-GC mining cables. RFID technology is widely used in a variety of applications, but this is a first for mining power cables. How does it work? An extremely small string of passive RFID chips is woven into the cable's core prior to jacketing. With a scanner and the Nexans Smart Inventory Management (SIM) app, customers can get real-time cable identification plus access to repair manuals, technical data, repair history and other key information to help their cable management program. A handheld scanner and mobile phone provide instant access to a cable's information in the field, while back in the office the SIM technology delivers a variety of desktop options and information tools. Of particular importance for trailing cables is its history of repair and length. These RFID chips, which are programmed in the AmerCable factory, require no external power and run the length of the cable. When spliced properly, the RFID chips will continue to provide information for the life of the cable. Cable managers can make note of each damage incident, repair and length after repair for future usage and reordering. Currently, AmerCable is offering RFID on SHD-GC and Mine Power Feeder cables. Contact your AmerCable rep for more information or mining.sales@nexans.com.

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania